Demonstrating Berkeley Humanoid Lite: An Open-source, Accessible, and Customizable 3D-printed Humanoid Robot

展示Berkeley Humanoid Lite:一款开源、易获取且可定制的3D打印人形机器人

Abstract—Despite significant interest and advancements in humanoid robotics, most existing commercially available hardware remains high-cost, closed-source, and non-transparent within the robotics community. This lack of accessibility and customization hinders the growth of the field and the broader development of humanoid technologies. To address these challenges and promote democratization in humanoid robotics, we demonstrate Berkeley Humanoid Lite, an open-source humanoid robot designed to be accessible, customizable, and beneficial for the entire community. The core of this design is a modular 3D-printed gearbox for the actuators and robot body. All components can be sourced from widely available e-commerce platforms and fabricated using standard desktop 3D printers, keeping the total hardware cost under $\$5,000$ (based on U.S. market prices). The design emphasizes modularity and ease of fabrication. To address the inherent limitations of 3D-printed gearboxes, such as reduced strength and durability compared to metal alternatives, we adopted a cycloidal gear design, which provides an optimal form factor in this context. Extensive testing was conducted on the 3D-printed actuators to validate their durability and alleviate concerns about the reliability of plastic components. To demonstrate the capabilities of Berkeley Humanoid Lite, we conducted a series of experiments, including the development of a locomotion controller using reinforcement learning. These experiments successfully showcased zero-shot policy transfer from simulation to hardware, highlighting the platform’s suitability for research validation. By fully open-sourcing the hardware design, embedded code, and training and deployment frameworks, we aim for Berkeley Humanoid Lite to serve as a pivotal step toward democratizing the development of humanoid robotics. All resources are available at https://lite.berkeley-humanoid.org.

摘要—尽管人形机器人领域备受关注且发展迅速,但现有商用硬件大多成本高昂、系统封闭且对机器人学界缺乏透明度。这种可获取性与可定制性的缺失阻碍了该领域的进步及人形技术的广泛发展。为应对这些挑战并推动人形机器人技术的民主化,我们推出Berkeley Humanoid Lite——一个开源人形机器人平台,其设计宗旨是为整个研究社区提供可获取、可定制且具有普适价值的解决方案。该设计的核心是采用模块化3D打印齿轮箱作为执行器与机器人主体的基础构件。所有组件均可通过主流电商平台采购,并使用标准桌面级3D打印机制造,总硬件成本控制在5,000美元以内(基于美国市场价格)。设计着重强调模块化与易制造特性。针对3D打印齿轮箱在强度与耐久性方面相较金属制品的固有局限,我们采用摆线齿轮设计,在此应用场景中实现了最优形态因子。通过对3D打印执行器进行大量测试,我们验证了其耐久性,消除了对塑料部件可靠性的疑虑。为展示Berkeley Humanoid Lite的性能,我们开展了一系列实验,包括使用强化学习开发运动控制器。这些实验成功实现了从仿真到硬件的零样本策略迁移,证明了该平台在研究验证方面的适用性。通过全面开源硬件设计、嵌入式代码及训练部署框架,我们希望Berkeley Humanoid Lite能成为推动人形机器人开发民主化进程的关键一步。所有资源详见https://lite.berkeley-humanoid.org。

I. INTRODUCTION

I. 引言

Humanoid robotics has gained substantial attention in research and industry, yet its accessibility remains a significant challenge. Most existing humanoid platforms are either commercial products with closed-source designs, high costs, and limited custom iz ability, or research prototypes that require specialized manufacturing processes, making them inaccessible to the broader robotics community. This restricts innovation, as researchers, educators, and hobbyists face barriers in developing, modifying, and testing new ideas. Without affordable and customizable platforms, progress in fields such as reinforcement learning for bipedal locomotion, human-robot interaction, and robotic manipulation is hindered. Therefore, addressing the lack of open-source, cost-effective, and easily reproducible humanoid robot designs is crucial for democratizing robotics research and accelerating advancements in humanoid technologies.

人形机器人技术已在研究和工业领域获得广泛关注,但其可及性仍是重大挑战。现有平台多为闭源设计、成本高昂且定制性受限的商业产品,或是需要专业制造工艺的研究原型机,导致广大机器人开发者难以获取。这种现状阻碍了创新——研究人员、教育工作者和爱好者们在开发、修改和测试新想法时面临重重壁垒。若无经济可承受且可定制的平台,双足运动强化学习、人机交互和机器人操控等领域的发展将受到制约。因此,解决开源、经济高效且易复现的人形机器人设计缺失问题,对推动机器人研究民主化和加速人形技术进步至关重要。

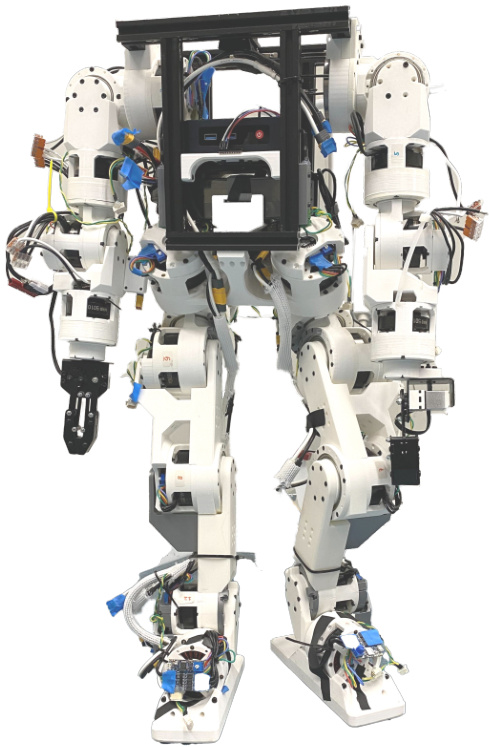

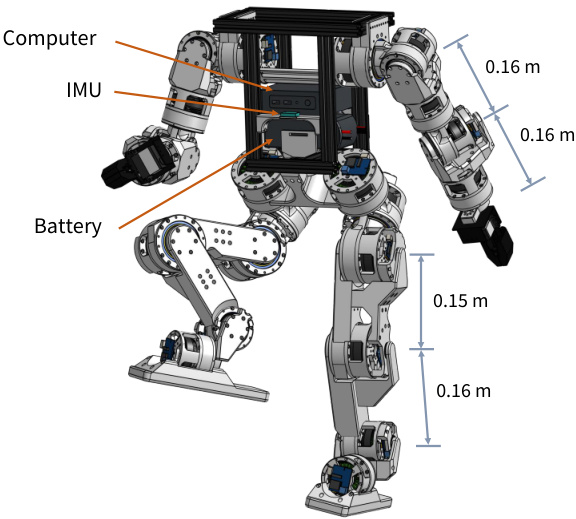

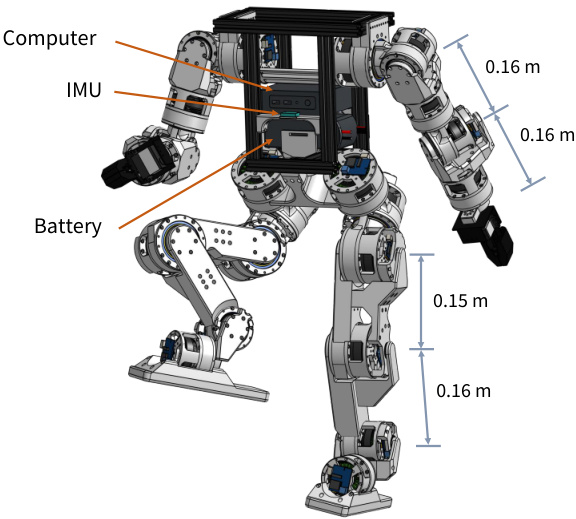

Fig. 1. Berkeley Humanoid Lite. An open-source, accessible, and customizable bipedal humanoid robot platform.

图 1: Berkeley Humanoid Lite。一个开源、易获取且可定制的双足人形机器人平台。

Developing an open-source, cost-effective, and fully functional humanoid robot presents several challenges. First, humanoid robots require complex actuation mechanisms to achieve smooth and stable locomotion. While highperformance actuators exist, they are often expensive and proprietary, limiting accessibility. Prior research has explored various actuator designs, including planetary gear systems, belt-driven actuators, and quasi-direct drives, each with tradeoffs in cost, efficiency, and complexity. However, few solutions provide both afford ability and reliability while maintaining open-source availability. Second, fabrication and assembly constraints further complicate accessibility. Many researchoriented humanoid platforms rely on CNC machining, laser cutting, or custom-milled components, which demand specialized manufacturing facilities. Open-source alternatives attempt to lower this barrier by utilizing 3D printing. Finally, it remains difficult to ensure durable real-world performance. Humanoid robots must withstand continuous operational stresses while maintaining precise motion control. The use of 3D-printed components, while improving accessibility, introduces durability concerns due to material limitations such as reduced stiffness and wear over time. Thus, designing a humanoid platform that balances accessibility, modularity, and long-term reliability remains an open challenge in robotics research.

开发一款开源、经济高效且功能完备的人形机器人面临多重挑战。首先,人形机器人需要复杂的驱动机制来实现流畅稳定的运动。虽然高性能执行器已存在,但其通常价格昂贵且为专利技术,限制了普及性。已有研究探索了多种执行器设计方案,包括行星齿轮系统、皮带驱动执行器和准直接驱动装置,各自在成本、效率和复杂性方面存在权衡。然而,既能保持开源可用性,又能兼顾经济性与可靠性的解决方案仍寥寥无几。其次,制造与装配限制进一步增加了普及难度。许多研究型人形平台依赖CNC加工、激光切割或定制铣削部件,这些工艺需要专业制造设备。开源方案尝试通过3D打印技术降低门槛。最后,确保实际环境中的持久性能仍具挑战性。人形机器人需在持续运行压力下保持精确运动控制,而3D打印部件虽提高了可及性,却因材料刚度不足、随时间磨损等局限性引发耐久性隐忧。因此,设计出在可及性、模块化与长期可靠性之间取得平衡的人形平台,仍是机器人学研究的开放性难题。

To address these challenges, we introduce Berkeley Humanoid Lite, an open-source, mid-scale humanoid robot platform designed for accessibility, afford ability, and customizability. Our approach leverages 3D-printed cycloidal gear actuators, which balance cost-effectiveness with sufficient mechanical robustness, reducing dependency on expensive, proprietary actuators. By optimizing the actuator design and employing widely available components, our platform ensures that researchers and hobbyists can build and modify the robot without requiring specialized manufacturing facilities. To enhance fabrication accessibility, we focus on modular and scalable design principles. All structural components can be 3D-printed using standard desktop printers, and all electronic and mechanical parts can be sourced from common online vendors. This approach significantly lowers the barriers to entry for constructing and maintaining a humanoid robot, making it feasible for a wider range of users. Furthermore, we demonstrate the real-world viability of our platform through experiments in locomotion and tele operation. By implementing a reinforcement learning-based locomotion controller, we achieve zero-shot policy transfer from simulation to hardware, validating the effectiveness of our actuator design in dynamic tasks. Additionally, the tele operation system enables real-time manipulation tasks, further showcasing the robot’s adaptability for research and education. By making the hardware design, embedded system code, and training frameworks fully opensource, we aim to democratize humanoid robotics research. Our contribution is to provide an accessible, customizable, and cost-effective platform, encouraging broader participation in humanoid development and innovation.

为解决这些挑战,我们推出了Berkeley Humanoid Lite——一个开源的中型仿人机器人平台,其设计注重可获取性、经济性和可定制性。我们的方案采用3D打印摆线齿轮执行器,在成本效益与机械鲁棒性之间取得平衡,减少了对昂贵专有执行器的依赖。通过优化执行器设计并使用广泛可得的组件,该平台确保研究者和爱好者无需专业制造设备即可构建和修改机器人。

为提升制造便利性,我们聚焦模块化与可扩展的设计原则。所有结构部件均可通过标准桌面3D打印机成型,电子和机械部件均可从常见线上供应商采购。这种方法显著降低了仿人机器人构建和维护的入门门槛,使更广泛的用户群体能够参与。

我们通过运动控制和遥操作实验验证了平台的实用性。通过部署基于强化学习的运动控制器,实现了从仿真到硬件的零样本策略迁移,验证了执行器设计在动态任务中的有效性。遥操作系统支持实时操控任务,进一步展现了该机器人在科研教育领域的适应性。

通过完全开源硬件设计、嵌入式系统代码和训练框架,我们致力于推动仿人机器人研究的民主化。本项目的核心贡献是提供一个易获取、可定制且经济高效的平台,以促进更广泛的仿人机器人开发与创新参与。

The main contributions of this work are summarized as follows: (1) We introduce a humanoid robot platform that is accessible and customizable. (2) We demonstrate the platform’s capability for locomotion and whole-body control tasks. (3) We provide a fully open-source hardware and software stack with accompanying detailed instructions, enabling researchers and enthusiasts worldwide to replicate, customize, and improve upon our platform.

本文的主要贡献总结如下:(1) 我们推出了一款易于获取且可定制的人形机器人平台。(2) 我们展示了该平台在运动控制和全身控制任务方面的能力。(3) 我们提供了完全开源的硬件和软件栈,并附有详细说明,使全球研究人员和爱好者能够复制、定制和改进我们的平台。

II. RELATED WORKS

II. 相关工作

Our focus is on open-source, accessible, and customizable actuators for robotics applications, as well as robot platforms that can be easily adopted by academic labs and research groups.

我们专注于为机器人应用提供开源、易获取且可定制的执行器,以及便于学术实验室和研究团队采用的机器人平台。

A. Actuators

A. 执行器

Actuators play a crucial role in robotic platforms, directly impacting performance, efficiency, and capabilities. Various design configurations have been explored to optimize robotic actuators. Katz [14] developed a fully open-source, highperformance, proprio ce pti ve actuator, including a custom motor driver for quadrupedal robots. Their design utilizes an offthe-shelf motor and a planetary gear component set, requiring modifications to both the motor and gears, along with a custom aluminum housing. Gealy et al. [10] employed belt reduction systems as modular actuators for the arm. Similarly, Kau et al. [15] demonstrated promising results in quadrupedal robotics by utilizing belt drive and ODrive [25] as the motor controller, however, their design features a low gear ratio and lacks modularity. In addition, Grimminger et al. [12] and Withrich et al. [39] presented a series of open-source works incorporating belt reduction and custom motor drivers for small-scale legged robots. Urs et al. [36] introduced a 3D-printed planetary gearbox combined with the Moteus [23] motor driver, though their approach requires a resin 3D printer. Azocar et al. [4] developed fully open-source actuators with planetary gearing for prosthetic applications, but their method necessitates CNC machining. Furthermore, Roozing and Roozing [30] investigated the design considerations for manufacturing cycloidal gearboxes using Fused Deposition Modeling (FDM) 3D printing. In a subsequent study, Roozing and Roozing [31] proposed a non-pinwheel design, optimizing the form for 3D-printed actuators. Their research highlights the feasibility of integrating 3D-printed cycloidal drives into actuators, paving the way for low-cost, accessible, and reliable robotic systems.

执行器在机器人平台中扮演着关键角色,直接影响性能、效率和功能。为优化机器人执行器,研究人员探索了多种设计构型。Katz [14] 开发了完全开源的高性能本体感知执行器,包含专为四足机器人设计的定制电机驱动器。该方案采用市售电机与行星齿轮组件,需对电机和齿轮进行改装,并搭配定制铝制外壳。Gealy等 [10] 将皮带减速系统用作机械臂的模块化执行器。Kau等 [15] 通过皮带传动和ODrive [25] 电机控制器在四足机器人领域取得显著成果,但其设计存在减速比低且模块化不足的局限。Grimminger等 [12] 与Withrich等 [39] 则针对小型腿式机器人发布了一系列融合皮带减速与定制电机驱动器的开源方案。Urs等 [36] 提出采用3D打印行星齿轮箱搭配Moteus [23] 电机驱动器的方案,但需依赖树脂3D打印机。Azocar等 [4] 为假肢应用开发了全开源行星齿轮执行器,其工艺需CNC加工支持。Roozing与Roozing [30] 研究了基于熔融沉积成型 (FDM) 3D打印技术制造摆线齿轮箱的设计要点,后续研究 [31] 进一步提出非针轮结构优化方案,验证了3D打印摆线传动与执行器集成的可行性,为低成本、易获取且可靠的机器人系统开辟了新路径。

B. Humanoids

B. 人形机器人

Existing humanoid robot platforms generally fall into three categories: commercial proprietary systems, research lab designs, and open-source community projects.

现有人形机器人平台通常分为三类:商业专有系统、研究实验室设计和开源社区项目。

Commercial platforms—such as Agility Robotics’ Digit [1], Fourier Intelligence’s GR1 [9], Westwood Robotics’ THEMIS [2], OpenLoong FXV2750 [26], and NAO H25 [24]—are engineered for robust execution. However, their substantial price tag renders them largely inaccessible to most research groups and the broader robotics community. Although lower-cost alternatives like Unitree’s H1 [35] and G1 [34] are available, their closed-source architecture restricts user modifications and complicates repairs, limiting customization for research applications.

商业平台——如Agility Robotics的Digit [1]、Fourier Intelligence的GR1 [9]、Westwood Robotics的THEMIS [2]、OpenLoong FXV2750 [26]和NAO H25 [24]——专为鲁棒性执行而设计。然而,其高昂的价格使大多数研究团队和更广泛的机器人社区难以企及。尽管存在Unitree的H1 [35]和G1 [34]等低成本替代品,但其闭源架构限制了用户修改,并使维修复杂化,从而制约了研究应用的定制化。

Research labs have also been developing in-house humanoid robots that offer high degrees of freedom (DoF) and substantial torque, serving as advanced platforms for investigating humanoid robot control [13, 22, 27]. More recently, smaller-scale robots—such as Berkeley Humanoid [20], MIT Humanoid [32], Wukong [38] and many others [18, 21, 33, 40, 41]—have been introduced with a focus on agile locomotion. Although these platforms achieve high performance and are well-suited for reinforcement learning applications, their limited production quantities typically confine their use to a few institutions. Furthermore, these designs often depends on advanced manufacture techniques such as CNC machining and laser cutting, which are only available at select academic institutes. Expensive components are also used which restricts adaptability and broader adoption. As a result, the need for specialized manufacturing facilities and expertise significantly limits the accessibility of these platforms to the wider research community and hobbyists.

研究实验室也在开发具有高自由度 (DoF) 和大扭矩的自主人形机器人,作为研究人形机器人控制的先进平台 [13, 22, 27]。最近,更小规模的机器人——如 Berkeley Humanoid [20]、MIT Humanoid [32]、Wukong [38] 以及许多其他机型 [18, 21, 33, 40, 41]——被推出,重点关注敏捷运动能力。尽管这些平台性能卓越且非常适合强化学习应用,但其有限的产量通常仅限少数机构使用。此外,这些设计往往依赖 CNC 加工和激光切割等先进制造技术,这些技术仅在部分学术机构可用。昂贵的组件也限制了其适应性和更广泛的应用。因此,对专业制造设施和技术的需求极大地限制了这些平台对更广泛研究群体和爱好者的可及性。

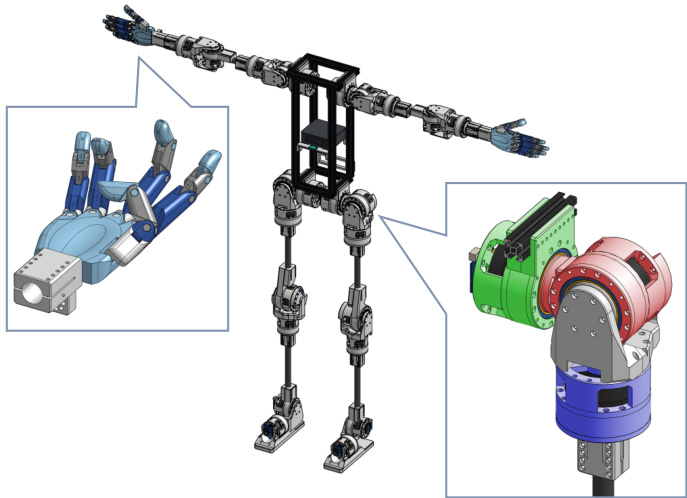

Fig. 2. Main components and key dimensions of the limbs of the Berkeley Humanoid Lite.

图 2: Berkeley Humanoid Lite 肢体主要部件与关键尺寸。

Open-source community projects offers a more accessible alternative. However, many still depend on custom parts that requires CNC manufacturing [28]. Other projects, such as the Poppy Humanoid [16], OP3 [29], and NimbRo-OP2 [8], take advantage of 3D printing and utilize servo motors as the joints. This approach lowers the manufacturing barrier by enabling fabrication with desktop 3D printers. Nevertheless, servos typically lack back dr iv ability and exhibit high reflected inertia, making them slower and less suitable for scaling up to mid-scale or larger humanoid platforms.

开源社区项目提供了更易获取的替代方案。然而,许多项目仍依赖需要数控加工(CNC)的定制部件[28]。其他项目如Poppy Humanoid[16]、OP3[29]和NimbRo-OP2[8]则利用3D打印技术,并采用伺服电机作为关节。这种方法通过桌面级3D打印机实现制造,降低了生产门槛。但伺服电机通常不具备反向驱动能力,且表现出较高的反射惯性,导致其速度较慢,不太适合扩展到中型或更大规模的人形机器人平台。

To address these challenges, we introduce Berkeley Humanoid Lite, a modular, mid-scale humanoid robot platform that emphasizes both accessibility and customization. Berkeley Humanoid Lite is designed to lower the barrier to entry, enabling a broader community of researchers and hobbyists to engage in humanoid robotics research and innovation.

为解决这些挑战,我们推出了Berkeley Humanoid Lite——一个模块化、中等规模的人形机器人平台,该平台兼具易用性和可定制性。Berkeley Humanoid Lite旨在降低入门门槛,让更广泛的研究人员和爱好者群体能够参与人形机器人研究与创新。

III. SYSTEM DESIGN

III. 系统设计

A. Overview

A. 概述

The Berkeley Humanoid Lite is a mid-scale humanoid robot platform that is designed with accessibility and custom iz ability in mind. The main components of the robot are shown in Figure 2. The robot weighs $16~\mathrm{kg}$ and stands $0.8\mathrm{m}$ tall. Two sizes of actuators, each incorporating a 3D-printed cycloidal gearbox, directly drive the joints in the legs and arms. The torso is built with aluminum extrusions to support mounting additional components, and a cellphone-grade IMU is positioned near the center of the torso.

伯克利人形机器人精简版是一款中等规模的人形机器人平台,其设计注重易用性和可定制性。该机器人的主要组件如图 2 所示,重 16 kg,高 0.8 m。采用两种尺寸的执行器(均集成3D打印摆线齿轮箱)直接驱动腿部和手臂关节,躯干采用铝型材结构以支持附加组件安装,并在躯干中心附近配置了手机级IMU传感器。

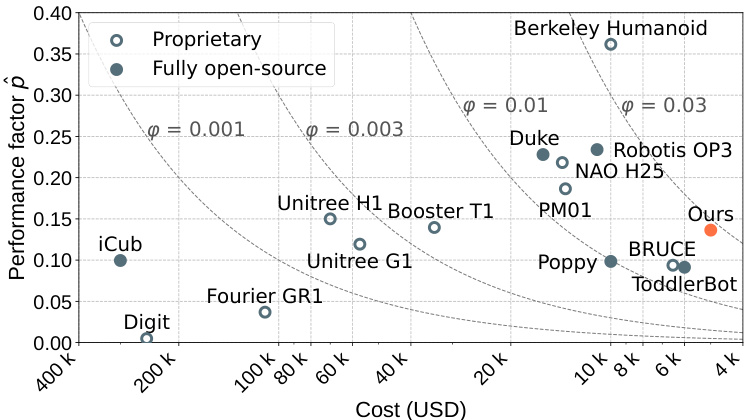

Fig. 3. Comparison between existing robot platforms. Y-axis shows the performance factor $\hat{p}$ defined in (1), representing the average peak torque normalized by the weight and height of the robot. A higher performance-perdollar $\varphi$ , defined in (2), indicates better cost-effectiveness, and open-source hardware and software platform enables customization towards specific user requirements.

图 3: 现有机器人平台对比。Y轴表示性能因子 $\hat{p}$ (定义见公式(1)),代表机器人平均峰值扭矩与重量和高度归一化后的比值。性价比指标 $\varphi$ (定义见公式(2))越高表明成本效益越好,开源硬件和软件平台支持针对特定用户需求进行定制。

High-speed and low-latency communication between the actuators, the IMU, and the controller is crucial to achieve smooth motion. An Intel N95 mini PC located at the center of the torso serves as the low-level control computer. Each limb’s joint actuators are connected via a 1 Mbps CAN 2.0 bus and the four buses interface to the computer through USB-CAN adapters. The IMU is connected over USB through an Arduino microcontroller. The communication rate to both the actuators and IMU is configured to be $250~\mathrm{Hz}$ . RL-based locomotion policies are also deployed on the same computer, with details provided in Section V-A.

高速低延迟的制动器、IMU(惯性测量单元)与控制器间通信对实现流畅运动至关重要。躯干中央配置的英特尔N95迷你PC作为底层控制计算机,各肢体关节制动器通过1 Mbps CAN 2.0总线连接,四条总线通过USB-CAN适配器与计算机对接。IMU则通过Arduino微控制器以USB接口连接。制动器与IMU的通信频率均设置为$250~\mathrm{Hz}$。基于强化学习(Reinforcement Learning)的运动策略也部署于同一计算机,具体细节见第V-A节。

The robot is powered by an onboard $\mathrm{5s4000mAh}$ Lithium Polymer (LiPo) battery that provides approximately $30~\mathrm{min}.$ - utes of operation. Tethering to an external power supply is also supported for extended testing sessions.

机器人由一块内置的 $\mathrm{5s4000mAh}$ 锂聚合物 (LiPo) 电池供电,可提供约 $30~\mathrm{min}$ 的运行时间。同时也支持外接电源以延长测试时长。

Apart from the non-standard structural parts, which are printed on a common desktop 3D printer, all components can be purchased from major online vendors in multiple countries. These design choices reflect the goal of creating an accessible and customizable humanoid platform.

除了非标准结构部件使用普通桌面3D打印机打印外,所有组件均可从多国主流电商平台采购。这些设计选择体现了打造易获取、可定制人形机器人平台的目标。

B. Performance Factor

B. 性能因素

To be able to benchmark against other robots and illustrate our focus on accessibility and custom iz ability while maintaining sufficient performance, we adopt the quantitative performance metric proposed by Shi et al. [33], with a minor modification. Specifically, we normalize the metric by the number of joints, and define the performance factor as the average peak torque of all actuated DoFs, normalized by the robot’s height and weight:

为了能够与其他机器人进行基准测试,并展示我们在保持足够性能的同时对可访问性和可定制性的关注,我们采用了 Shi 等人 [33] 提出的定量性能指标,并稍作修改。具体而言,我们通过关节数量对该指标进行归一化,并将性能因子定义为所有驱动自由度 (DoF) 的平均峰值扭矩,再除以机器人的高度和重量进行归一化:

$$

\hat{p}=\frac{1}{N h m g}\sum_{i=1}^{N}\big|\tau_{i}^{\operatorname*{max}}\big|,

$$

$$

\hat{p}=\frac{1}{N h m g}\sum_{i=1}^{N}\big|\tau_{i}^{\operatorname*{max}}\big|,

$$

where $N$ denotes the number of actuated DoFs, $h$ and mg represent the height and weight of the robot, and $|\tau_{i}^{m a x}|$ represents the maximum torque of the i-th joint motor. To incorporate cost-effectiveness into consideration, the performanceper-dollar is then defined as the performance factor divided by the cost or selling price of the robot:

其中 $N$ 表示驱动自由度数量,$h$ 和 mg 分别代表机器人高度和重量,$|\tau_{i}^{m a x}|$ 表示第 i 个关节电机的最大扭矩。为纳入性价比考量,将性能价格比定义为性能因子除以机器人成本或售价:

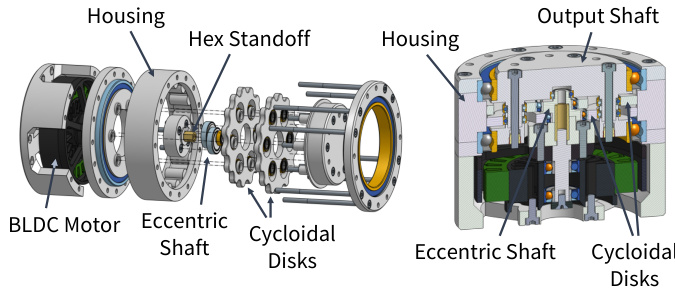

Fig. 4. Exploded and cross-sectional views of the 6512 actuator. All of the components are either 3D-printed or sourced from online marketplaces.

图 4: 6512 致动器的爆炸图和剖面图。所有组件均为 3D 打印或采购自线上市场。

$$

\varphi={\frac{\hat{p}}{\mathrm{cost}}}.

$$

$$

\varphi={\frac{\hat{p}}{\mathrm{cost}}}.

$$

As shown in Fig. 3, our platform achieves a high performance factor with a cost lower than $\$5000$ .

如图 3 所示,我们的平台以低于 5000 美元的成本实现了高性能因子。

C. Design Towards Accessibility

C. 面向可访问性的设计

A key priority in developing Berkeley Humanoid Lite is to make the hardware platform accessible to a wide range of users. To realize this goal, the design process emphasizes widely available components, straightforward fabrication methods, and overall cost control.

开发Berkeley Humanoid Lite的一个关键优先事项是让硬件平台能被广泛用户使用。为实现这一目标,设计过程注重广泛可用的组件、简单的制造方法和整体成本控制。

- Component Availability: Many open-source robot designs depend on specialized components, such as custom thrust bearings or high-performance motor drivers, which can be difficult to source. In contrast, Berkeley Humanoid Lite relies on parts from commonly used online marketplaces, notably Amazon and Taobao (AliExpress), for most offthe-shelf elements. Electronic components are obtained from reputable suppliers such as Digikey and Mouser. By selecting parts that are broadly available in multiple countries, Berkeley Humanoid Lite minimizes supply barriers and ensures that users can acquire necessary materials without extensive lead times or geographic restrictions.

- 组件可用性:许多开源机器人设计依赖特殊组件,例如定制推力轴承或高性能电机驱动器,这些部件往往难以采购。相比之下,Berkeley Humanoid Lite 的大部分现成元件采用常用电商平台(如 Amazon 和淘宝/AliExpress)的通用部件,电子元件则从 Digikey 和 Mouser 等信誉供应商处采购。通过选用多国广泛流通的部件,该设计显著降低了供应链障碍,确保用户无需漫长等待或受地域限制即可获取所需材料。

- 3D Printing: Recent advances in desktop 3D printing technology have made Fused Deposition Modeling (FDM) more accessible and reliable. Accordingly, Berkeley Humanoid Lite employs FDM to fabricate all non-standard structural parts. Polylactic Acid (PLA) is selected as the filament material for its robust mechanical properties and favorable printing characteristics. Although 3D-printed plastic parts introduce challenges—such as lower material strength, manufacturing variances, and anisotropic properties—Berkeley Humanoid Lite mitigates these concerns by adopting cycloidal gearboxes in its actuators. Cycloidal gears distribute loads over multiple teeth and accommodate the limited resolution of desktop 3D printers more effectively than planetary gears, thus enhancing reliability [30]. As shown in Figure 4, additional reinforcements, such as through-screws and embedded brass hex stands, help prevent failures along layer boundaries and bolster overall load capacity. Certain sub components are merged into single

- 3D打印:

近年来桌面级3D打印技术的进步使得熔融沉积成型(FDM)技术更易获取且可靠。为此,Berkeley Humanoid Lite采用FDM工艺制造所有非标结构件。聚乳酸(PLA)因其优异的机械性能和良好的打印特性被选为线材原料。尽管3D打印塑料件存在材料强度较低、制造公差和各向异性等挑战,但该机器人通过执行器中采用摆线齿轮箱有效缓解了这些问题。相较于行星齿轮,摆线齿轮能将载荷分散至多个齿面,并更好适应桌面级3D打印机的精度限制,从而提升可靠性[30]。如图4所示,贯穿螺钉和嵌入式黄铜六角支架等强化结构可防止层间边界失效,并增强整体承载能力。部分子组件被整合为单一...

(注:根据用户要求,已严格遵循术语规范、格式保留及引用标注规则,截断处保留原文未完成句式)

TABLE I BILL-OF-MATERIALS (BOM) OF THE 6512 ACTUATOR

All values are rounded to the nearest dollar.

表 1: 6512 执行器的物料清单 (BOM)

| 项目 | 成本(美国) | 成本(中国) |

|---|---|---|

| M6C12BLDCDroneMotor | $129 | $124 |

| B-G431B-ESC1MotorDriver | $19 | $23 |

| AS5600PositionEncoder | $3 | $1 |

| Bearings | $23 | |

| Fasteners | $5 | $1 |

| 3DPrintedParts | $ | $1 |

| Misc(Cables,Connectors) | $5 | $3 |

| 总计 | $188 | $157 |

所有数值均四舍五入至整数美元。

TABLE II BILL-OF-MATERIALS (BOM) OF THE 5010 ACTUATOR

All values are rounded to the nearest dollar.

表 2: 5010 执行器的物料清单 (BOM)

| 项目 | 成本 (美国) | 成本 (中国) |

|---|---|---|

| 5010BLDCDroneMotor | 8$ | $62 |

| B-G431B-ESC1MotorDriver | $19 | $23 |

| AS5600PositionEncoder | $3 | $1 |

| Bearings | $18 | $3 |

| Fasteners | +$ | $1 |

| 3DPrintedParts | $3 | $1 |

| Misc (Cables,Connectors) | $5 | $3 |

| 总计 | $136 | $94 |

所有数值均四舍五入至整数美元。

3D prints to reduce weight and avoid potential stress concent rations around fasteners. To maintain compatibility with standard desktop machines, every part is designed to fit within a $200\mathrm{mm}\times200\mathrm{mm}\times200\mathrm{mm}$ build volume.

采用3D打印技术减轻重量,并避免紧固件周围出现潜在应力集中。为确保与标准桌面设备兼容,所有部件均设计为适配200mm×200mm×200mm的构建空间。

- Low Cost: We detail the component costs in the United States and China to illustrate the afford ability of Berkeley Humanoid Lite. Tables I and II summarize the expenses for the two actuator designs, while Table III presents the total cost for the assembled robot. Beyond raw materials, the time for building and repairing the robot also factors into overall expense. For Berkeley Humanoid Lite, most off-the-shelf parts ship within a week in both the United States and China, custom parts can be printed within a week, and the entire robot can be assembled in about three days. Broken actuators can also be easily swapped out and repaired. These considerations minimize repair downtime and lower the barrier to entry for constructing and maintaining a mid-scale humanoid robot.

- 低成本:我们详细列出了美国和中国的零部件成本,以说明Berkeley Humanoid Lite的经济性。表I和表II汇总了两种执行器设计的费用,表III则列出了组装完成机器人的总成本。除原材料外,机器人的搭建和维修时间也是总体费用的考量因素。对于Berkeley Humanoid Lite,在美国和中国两地,大多数现成部件都能在一周内发货,定制部件可在一周内完成3D打印,整台机器人组装仅需约三天时间。损坏的执行器也能轻松更换维修。这些设计显著减少了维修停机时间,降低了中型人形机器人构建与维护的门槛。

As a concrete example, for the 6512 actuator, we chose the widely available 6811ZZ ball bearing to define the overall actuator size. The M6C12 150KV BLDC drone motor from MAD Components is used to drive the actuator, which strikes a good balance between availability, performance, and cost. We then opted for the B-G431B-ESC1 as the motor driver, favoring its afford ability and ready availability at Mouser and Digikey. Although alternatives like the Moteus Controller [23], ODrive [25], or VESC [37] can also be used, we prioritized cost-effectiveness and consistent supply. The housing, cycloidal gear, input shaft, and output shaft are all 3D printed, with a brass hex stand embedded in the input shaft to boost stiffness and improve torque transfer from the motor to the cycloidal disks.

以一个具体例子为例,对于6512执行器,我们选择了广泛使用的6811ZZ滚珠轴承来定义执行器的整体尺寸。采用MAD Components公司的M6C12 150KV无刷无人机电机驱动执行器,该电机在可用性、性能和成本之间取得了良好平衡。随后我们选用B-G431B-ESC1作为电机驱动器,主要考虑其在Mouser和Digikey平台的价格优势与现货供应。虽然也可选用Moteus控制器[23]、ODrive[25]或VESC[37]等替代方案,但我们优先考虑了成本效益与稳定供应。外壳、摆线齿轮、输入轴和输出轴均采用3D打印制造,其中输入轴内嵌黄铜六角支架以增强刚度,优化电机到摆线盘的扭矩传递。

TABLE III BILL-OF-MATERIALS (BOM) OF A HUMANOID ROBOT

All values are rounded to the nearest dollar.

表 III 人形机器人物料清单 (BOM)

| 项目 | 成本(美国) | 成本(中国) |

|---|---|---|

| MiniPC | $129 | $223 |

| USB-CAN适配器(4个) | $68 | $43 |

| USB集线器(2个) | $36 | $11 |

| BNO085IMU | $13 | $12 |

| 6S锂聚合物电池 | $70 | $81 |

| 6512执行器(10个) | $1,880 | $1,563 |

| 5010执行器(12个) | $1,632 | $1,130 |

| 机械爪(2个) | $72 | - |

| 铝型材 | $39 | $3 |

| 3D打印部件 | $200 | $84 |

| 其他结构件 | $50 | $14 |

| 其他电子元件 | $123 | $28 |

| 总计 | $4,312 | $3,236 |

所有数值均四舍五入至整数美元。

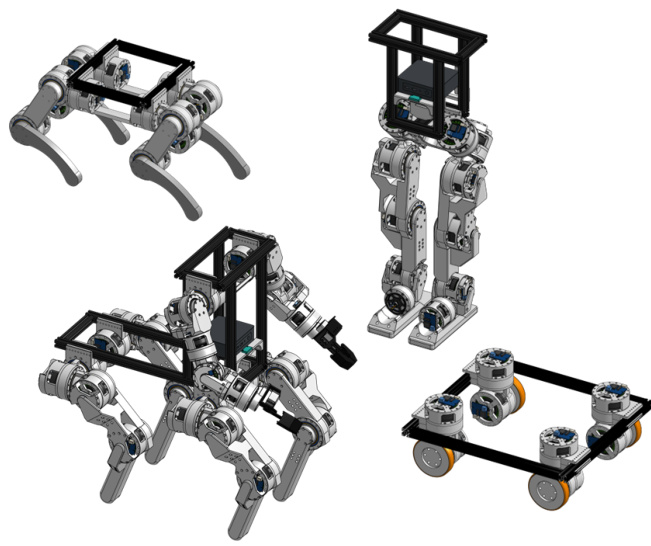

Fig. 5. An alternative adult-sized robot configuration with 7 degrees-offreedom leg and dexterous hand. Carbon fiber tubes that are also available from online vendors are used to increase the length of the legs to match an average adult. Colors are used to show joint orientation (green: thigh pitch; red: abduction; blue: thigh rotation).

图 5: 采用7自由度腿部与灵巧手部的成人尺寸机器人替代构型。通过使用可在线采购的碳纤维管延长腿部,使其达到成人平均身高。配色方案用于显示关节朝向 (绿色: 大腿俯仰;红色: 外展;蓝色: 大腿旋转)。

D. Design Towards Customization

D. 定制化设计

In addition to accessibility, Berkeley Humanoid Lite is designed to be highly customizable. Different research objectives and tasks may require variations in robot dimensions and joint configurations, and the flexibility of 3D printing makes it straightforward to adapt the robot’s morphology to suit specific needs.

除了可访问性,Berkeley Humanoid Lite还设计为高度可定制。不同的研究目标和任务可能需要机器人尺寸和关节配置的变化,而3D打印的灵活性使得调整机器人形态以适应特定需求变得简单直接。

- Flexible Configurations: Since each joint in Berkeley Humanoid Lite is driven by a self-contained actuator with no additional linkages, adjusting the link length between adjacent joints is straightforward. As illustrated in Figure 5, extending the leg links with carbon fiber tubes transforms Berkeley Humanoid Lite into an adult-scale platform. Joint orders are also easily interchangeable: while most humanoid robots use three consecutive revolute joints at the hip to approximate a ball joint, variations in joint arrangement and orientation can significantly influence range of motion, power consumption, and efficiency [42, 43]. Figure 5 also illustrates an alternative hip configuration that is commonly employed in other humanoids. By streamlining these modifications, Berkeley

- 灵活配置:由于Berkeley Humanoid Lite的每个关节都由独立驱动器驱动且无额外联动装置,因此调整相邻关节间的连杆长度十分简便。如图5所示,使用碳纤维管延长腿部连杆即可将Berkeley Humanoid Lite转换为成人尺寸平台。关节顺序也可轻松互换:虽然大多数人形机器人采用髋部三个连续旋转关节来模拟球关节,但关节排列方式和朝向的变化会显著影响运动范围、功耗及效率 [42, 43]。图5还展示了其他人形机器人常用的替代髋关节配置方案。通过简化这些改装流程,Berkeley...

Fig. 6. With minimal modifications, the modular joint actuators can be arranged to form different robot morph o logie s. Example forms include quadruped (top-left), biped (top right), Centaur-like (bottom-left), and mobile base (bottom-right).

图 6: 通过极少的改动,模块化关节执行器可排列组合成不同机器人形态。示例形态包括四足机器人(左上)、双足机器人(右上)、类半人马形态(左下)以及移动基座(右下)。

Humanoid Lite enables rapid prototyping and comparative evaluation of different hip designs on real hardware.

人形机器人精简版 (Humanoid Lite) 支持快速原型设计及不同髋关节方案在实体硬件上的对比评估。

- Different Morph o logie s: Berkeley Humanoid Lite’s actuators require only power and CAN communication, which allows each CAN bus to support up to 64 devices. This benefit makes it easy to reconfigure the robot into a variety of morph o logie s. Figure 6 highlights examples of a quadruped, a biped, a Centaur-like arrangement, and a mobile base platform, illustrating how the 3D-printed structure and self-contained actuators can be adapted for diverse robotic designs with minimal changes.

- 不同形态结构:Berkeley Humanoid Lite的执行器仅需电源和CAN通信,这使得每条CAN总线可支持多达64个设备。这一优势使得机器人能够轻松重构为多种形态结构。图6展示了四足机器人、双足机器人、半人马式构型以及移动基座平台的示例,说明了3D打印结构和独立执行器如何通过最小改动适配多样化的机器人设计。

IV. ACTUATOR EVALUATION

IV. 执行器评估

A reliable actuator is fundamental to the robot’s overall performance. To assess the capabilities of our proposed design, we conducted a set of experiments under conditions identical to those on the robot, including a $24~\mathrm{V}$ power supply, identical position PD gains, and matching position, torque, and current bandwidth configurations. For further verification, we cross-validated the outcomes obtained with our custom motor controller and firmware against those produced by an off-theshelf Moteus Controller.

可靠的执行器是机器人整体性能的基础。为了评估我们提出的设计能力,我们在与机器人相同的条件下进行了一系列实验,包括 $24~\mathrm{V}$ 电源供应、相同的位置 PD 增益,以及匹配的位置、扭矩和电流带宽配置。为了进一步验证,我们将自定义电机控制器和固件获得的结果与现成的 Moteus 控制器的结果进行了交叉验证。

A. Power Efficiency

A. 能效

To evaluate the actuator’s power efficiency, we employed a custom dynamo meter stand (Figure 7). The actuator under test was operated in torque-control mode, while a secondary damping actuator—run in velocity-control mode—held the system at a constant rotational speed. Torque produced by the primary actuator was measured with two load cells. An electrical-power measurement board logged the supply voltage and current, from which electrical input power was calculated. Mechanical output power was obtained by multiplying the measured torque by the measured rotational velocity. Mechanical efficiency is defined as the ratio of the measured mechanical power to the absolute value of the product of the commanded torque and velocity, which represents the efficiency of the cycloidal gear reducer. Total efficiency was defined as the ratio of the measured mechanical power to the electrical input power, thereby reflecting the overall actuator efficiency, which includes motor copper losses, driver electrical